This Selection Guide is designed to help automotive, aerospace, and other companies with discrete manufacturing operations to evaluate and select the best possible Manufacturing Execution System (MES) to meet their specific needs.

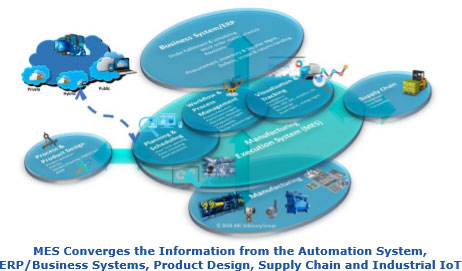

Enterprise MES/MOM solutions and intuitive user experience are key to collaboration, performance improvements, and optimizing production. Today, this is particularly important, as manufacturers need to personalize and change production quickly to remain competitive. Being able to collaborate across the enterprise and quickly access the information and manufacturing intelligence can greatly improve efficiencies and reduce production costs; another reason that MES and manufacturing will be more autonomous in the future. MES software is a key technology for digital transformation, smart manufacturing, and enabling companies to overcome production challenges such as frequent demand changes and reducing costs. Modern MES solutions are able to rapidly adapt to new innovative processes and business practices and maintain competitive advantage.

Process complexity and digital transformation are making it necessary for MES to support end-to-end operations and manufacturing from raw materials to the warehouse. We live in a world where more and more devices and things are connected, and this requires interoperability, ease of use, and human-factored user experience. Digital transformation, Industry 4.0, and MES are all about manufacturing efficiency—how quickly one can make production changes, enforce standards, and how quickly one can understand the process and get the information to the right user at the right time, and how quickly and securely one can take actionable insights. Speed, performance, flexibility, optimization, cybersecurity, accessibility, and context are important because users need to react quickly. Autonomous data collection and other capabilities (auto-recognize, auto-maintenance, etc.) are helping to increase speed to deploy and maintain MES. Virtual reality and digital twins are being integrated for process innovation. Intuitive user experience is being designed into MES so that users can collaborate better across the enterprise.

Process complexity and digital transformation are making it necessary for MES to support end-to-end operations and manufacturing from raw materials to the warehouse. We live in a world where more and more devices and things are connected, and this requires interoperability, ease of use, and human-factored user experience. Digital transformation, Industry 4.0, and MES are all about manufacturing efficiency—how quickly one can make production changes, enforce standards, and how quickly one can understand the process and get the information to the right user at the right time, and how quickly and securely one can take actionable insights. Speed, performance, flexibility, optimization, cybersecurity, accessibility, and context are important because users need to react quickly. Autonomous data collection and other capabilities (auto-recognize, auto-maintenance, etc.) are helping to increase speed to deploy and maintain MES. Virtual reality and digital twins are being integrated for process innovation. Intuitive user experience is being designed into MES so that users can collaborate better across the enterprise.

Buyers should look for products that provide complete tracking and genealogy capabilities, meet government regulations, and enable partners to track production. Complying with regulations using track and trace and serialization is important to ensure product quality and accuracy. The ability to track and trace and serialization from the raw materials through the supply chain and often to the customers are strong drivers for usage. This is particularly true for automotive, aeronautics & defense, consumer products, electronics, semiconductors, and hazardous materials.

Modern MES user interfaces should be more intuitive and easier to use than previous generation systems, and the digital dashboards should deliver intelligence and visualization that is specific to the product being made and the role of the person making decisions. Newer auto capabilities should enable the user with simpler, easier to use, visualize tools.

The software should make data more accessible in dashboards or reports that enhance the user experience and enable users the ability to make sense of the data and digital thread.

Use software and applications that enable remote workers and helps make operational data-driven decisions faster and is scalable to accommodate large volumes of data regardless of where the applications are stored–on-premise, in the cloud, or on the edge.

Simplified intuitive user experience (UX) is very important. The ability for remote workers to access manufacturing intelligence easily and securely has emerged as another key characteristic. The MES must be easy to deploy, integrate, simple to use, intuitive, and collaborative. The technology must be able to connect to the data easily and have flexible, yet interoperable and modular applications that adapt easily to manufacturing changes. The software should be scalable and adapt quickly to new innovative technologies and applications as they emerge. Because user experience is so important, ARC is also seeing an interest in digital twins, simulation, augmented reality, virtual reality, and improved digital dashboards. Augmented and virtual reality is being used to enforce workflow and operational insights. Simulation is being used to enable better workflow. Specialized, easy-to-design dashboards, and adaptable mobile capabilities improve human process interaction and collaboration can have a huge impact on worker insights and manufacturing efficiencies.

For more information or to purchase the MES for Discrete Selection Guide, please contact us.

Learn more about ARC's Technology Supplier Evaluation and Selection Guides

Learn more about ARC Strategic Services at Advisory Services for Industry Leaders