The General Motion Control (GMC) Selection guide is designed to help organizations select the best general motion control technologies and supplier for their unique business requirements.

Choosing the right general motion control supplier and technologies to operate your plant can be one of the most important decisions you will make for your business operations for years to come. If you are unsure about any of the key trends in the market or are in need of purchasing criteria, then you need the assistance that ARC Advisory Group has to offer.

Global megatrends are rapidly transforming industrial operations of end users. Suppliers must now embrace smart technologies and have deep application knowledge to offer valued solutions to end users. To this end, digitalization presents a huge opportunity for end users and suppliers. While digital transformation is picking up speed and is a catalyst for long-term competitive advantages for end users, this digital technology also creates new business opportunities and better services for suppliers. Digitalization helps create a path for the transition toward more connected and smarter systems to enhance overall process efficiency.

Digitalization offers numerous benefits to industrial operations. For example, digitalizing the assets and using cloud-based architecture with predictive analytics enable end users to monitor the health and performance of assets, allowing them to predict equipment failures before they happen and minimizing unnecessary shutdown that can cost millions of dollars. End user companies could make significant improvements in their operating performance, enabling them to succeed in today’s highly competitive market by embracing such technologies. Therefore, it is vital to seek suppliers that can become effective partners in this digitalization journey.

The following are a few of the supplier and technology selection issues that end users should consider:

The selection of components and final integration into production machinery are relatively complex processes. As machine builders continue to improve both mechanical and electrical designs, it is ever more critical to develop a strategic plan that embraces the latest trends in technology. Developing a strategic roadmap is essential as it provides a vision for your organization to embrace as well as communicate to your customers that you are forward-thinking.

Industrial analytics is currently primarily focused on machine learning, a branch of artificial intelligence (AI) that uses algorithms to mimic human recognition. Machine learning is often combined with AI for applications like chatbots and natural language processing. However, labeling machine learning as "AI" or "AI and machine learning" can cause confusion. Machine learning is widely used in manufacturing for predictive analytics, using supervised techniques for

identification and unsupervised learning for pattern discovery. It excels in recognizing patterns and predicting behaviors in large datasets without explicit instructions, crucial in asset-intensive settings with varying operating conditions. In discrete manufacturing, machine learning has brought numerous advantages, such as a 40 percent reduction in scrap by identifying inefficiencies and 90 percent accurate detection of quality issues in motorcycle manufacturing, allowing for early detection and prevention of problems.

OPC UA has become the tool of choice for linking the connectivity to a cloud platform, so look for suppliers and OEMs that support this protocol. There is already a wide range of products out there that support it, including barcode readers.

Preventative maintenance has been the protection against unscheduled downtime, which costs time and money and significantly impacts productivity and availability of production machinery. With the trend toward digitalization, end users can identify degrading assets and predict failure well in advance using data from smart devices with built-in connectivity. Servo drives, for example, can monitor changes in current or voltage to detect changes in torque demand that could indicate a problem like bearing wear or breakdown in a moving machine part. Such technology, along with advanced analytics, supports predictive maintenance, reducing or eliminating the time spent on preventative maintenance because now asset owners can schedule repairs at a convenient time prior to catastrophic failure.

Predictive maintenance has been kicked around for many years because it offers a huge benefit to the asset owners. With new technological environment of digitalization and advanced analytics, it is expected to gain rapid adoption in the market.

Users need to evaluate a supplier for not only its product portfolio, but also its solution capabilities for automation solutions. End users need to evaluate suppliers for the important aspects of application. These aspects include:

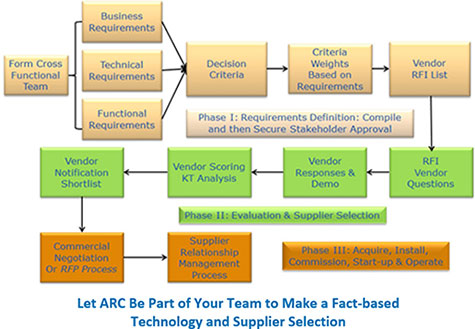

The selection process begins with a definition of the scope of the project, including production processes, number of plants, and integration with other systems. With this understanding, an organization can make the appropriate team member assignments. Reviewing and editing the ARC-provided selection criteria to ensure that the list fits your needs requires a team effort. ARC recommends that once the list is complete, you develop the appropriate questions for suppliers. This organized and logical list of criteria can provide the basis for a Request for Information (RFI) that you send to suppliers you wish to consider. Evaluating supplier responses and developing a final ranking of RFI results is also a team effort. This process helps ensure inclusive, fact-based, impartial supplier evaluations and selections, while avoiding bias issues that typically hamper these activities. Incorporating the ARC selection criteria helps reduce effort and timespan for a supplier selection process, providing faster time to benefit.

For more information or to purchase the General Motion Control Systems Selection Guide, please contact us.

Learn more about ARC's Technology Supplier Evaluation and Selection Guides

Learn more about ARC Strategic Services at Advisory Services for Industry Leaders