What are the trends for enterprise asset management (EAM) solutions,  and where is the domain going in the future? This ARC View examines the recent past and current trends to assess what the future holds across seven aspects of EAM: application focus, management objective, breadth/footprint, scheduling capabilities, mobility for work orders, predictive maintenance adoption, and software deployment. By examining the path of EAM across these dimensions, we can gain a clear view of the near future for EAM, computerized maintenance management systems (CMMS), and field service management (FSM).

and where is the domain going in the future? This ARC View examines the recent past and current trends to assess what the future holds across seven aspects of EAM: application focus, management objective, breadth/footprint, scheduling capabilities, mobility for work orders, predictive maintenance adoption, and software deployment. By examining the path of EAM across these dimensions, we can gain a clear view of the near future for EAM, computerized maintenance management systems (CMMS), and field service management (FSM).

EAM software suppliers can use these trends as a basis for product planning. Users should consider these trends in their software selection criteria.

Most change – particularly for mature markets like EAM – occurs organically by adopting new technologies and building on existing capabilities. Examining technology trends for the recent past provides a guide to a probable future. ARC Advisory Group has been researching the EAM area for over 25 years and is thus well-positioned to provide this perspective.

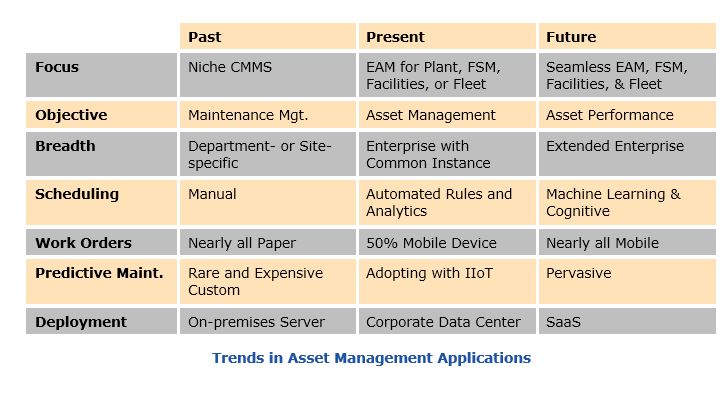

In the past, a CMMS supplier tended to focus on a particular niche to differentiate itself from other suppliers. To serve its customer base and remain competitive, each supplier deepened its capabilities for a type of asset. These solutions evolved into the current day applications that tend to focus on asset types, i.e., EAM for plant equipment, FSM, facilities, and fleet. However, nearly every business has a combination of these asset types. In the future, leading suppliers will offer one application that seamlessly manages all types of assets.

In the past, EAM focused on managing the resources within the maintenance function, including people, parts, and documentation. Now, the scope has grown to comprise managing the lifecycle of the asset, including financial aspects. In the future, IIoT-enabled remote monitoring and other capabilities will support asset optimization across both maintenance and operations to enable overall asset performance management (APM). Trade-offs, including parameters like equipment capability, asset health, energy utilization, and quality/yield, will be applied to meet production schedules with low risk and cost.

CMMS focused on managing maintenance resources and each department could sometimes select its software supplier. Often, this became plant-specific, but sometimes it extended to each department within the plant. Now, a business unit will typically have a single instance on a corporate or hosted server that supports multiple plants. As equipment becomes increasingly complex, more maintenance will need to be outsourced (using IIoT) to the OEM or a service organization specializing in that type of device. This trend will increasingly require visibility into the capabilities and status of those external resources which will need to be managed as an extended enterprise within EAM.

In the past, most maintenance was reactive. Schedules, typically established manually, lacked consideration for capacity and availability of resources, and thus were only followed loosely, if at all. Now, scheduling assesses skills and parts availability and includes some analytics for optimization. In the future, scheduling will be automated and optimized using machine learning and cognitive computing.

The business process for executing work orders by the technician is undergoing a digital transformation. In the past, the typical business process involved printing work orders, hand-written data entry by the technician when time permitted (sometimes at the end of the shift), and an administrative person entering the data into the EAM system. Data quality issues occurred for a variety of reasons including the technician not valuing the data (it is used by someone else), poor handwriting, timing delays, and more. se data quality issues often cause supervisors to lose confidence in the EAM system which then devolves into a record of what was done, rather than a proactive planning tool.

ARC’s research indicates that 50 percent of technicians now use a mobile device for work orders. The technician enters the data while performing the work. The software provides pick lists, format identification, and other data validation that assures high data integrity. The administrative person is no longer needed for data entry, removing that source of errors. The corresponding EAM system becomes a trusted planning and scheduling tool with higher productivity for all those involved. In the future, ARC expects that nearly all work orders will be managed via mobile devices.

Prior to IoT, adoption of predictive maintenance (PdM) was low since it involved an expensive and high-risk custom project. A development project included data acquisition, data management, analytics, and integration with other applications. The project team would use technologies that made sense at the time and then disband when the project was done. When something changed in the technologies deployed or integrated applications (like an upgrade), the PdM application would often break and, without the project team, the application would go away.

IIoT provides lower development costs, and fewer technology risks. The IIoT platform provides a sustainable IT infrastructure, and the development focuses on choosing services for building the application. Today, the under-served need for predictive maintenance has become the primary application of industrial IoT. With PdM, work occurs when truly needed, which reduces maintenance costs while also improving reliability. In the future, these business drivers and further ease-of-use improvements in the technologies will allow IIoT and PdM to become pervasive.

EAM, along with nearly all enterprise software domains, is migrating from an on-premises server to a data center (private or public) and – increasingly – to the SaaS model. This has improved IT resource utilization by outsourcing commodity IT skills (like desktop software and server maintenance), and focusing them on applications that run the business.

Technology adoption had a huge impact on EAM software capabilities in the past. This will continue in the near future. IIoT enables the addition of equipment data needed by maintenance to the process data used by operations. Nearly the entire EAM space is now adopting strategies to utilize the equipment data to lower costs and improve reliability. As organizations assimilate the changes in EAM, they will see opportunities to optimize across maintenance and operations for APM. This provides a business case focused on return on assets (ROA) that aligns with executive metrics as well as insight into where the market will go in the future.

Note: This ARC View was prepared with input from Ron Wallace of IBM, who has over 30 years of experience with EAM and CMMS applications.

ARC Advisory Group clients can view the complete report at ARC Client Portal on New Client Portal or Office 365 or Box.com on this website.

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: EAM, CMMS, FSM, PdM, APM, IIoT, SaaS, ARC Advisory Group.