ARC Technology Leadership Report January 2024

In the usually conservative and slow-moving landscape of industrial manufacturing, recent breakthroughs in (generative) artificial intelligence (AI) have hit like a tsunami, causing companies to take a fresh look at industrial AI and its potential for reshaping operational paradigms and propelling organizations into the future. This report delves into the contrasting practices of industrial manufacturing end users, categorizing them into leaders, mainstream, and laggards based on their adeptness in implementing not just generative AI technologies but the broad range of AI tools and techniques that ARC has defined as ‘Industrial AI.’ As we explore the multifaceted dimensions of AI adoption within these companies, across IT, OT, and ET systems, processes, and the workforce, an examination of the strategies, challenges, and outcomes embraced by both leaders and laggards unveils critical insights into the divergence of their trajectories. By scrutinizing these distinct differences, this report seeks to elucidate the crucial role played by AI in redefining best-in-class manufacturing and to provide actionable intelligence for organizations looking to navigate these intricate technologies and ensure competitive excellence.

Industrial companies face many challenges and will continue to do so in the future. Whether it is political unrest, climate disruption, pandemics, or global macroeconomic uncertainty, companies are concerned about their operational resilience and agility. Industrial companies routinely face pain points and cost drivers such as energy costs, supply chain disruptions, material shortages, rising prices, workforce dynamics, sustainability requirements and more. Advances in AI could not have come at a better time to help mitigate these challenges and improve business operations to not only ensure short and long term viability but to increase one’s competitive advantages in the marketplace.

Achieving industrial grade AI can be challenging, if not daunting, as it requires an understanding of business objectives and the integration of AI technology with industrial processes and systems. Furthermore, implementing AI requires the collaboration and coordination of multiple stakeholders with diverse perspectives, expertise, and objectives. By comparing themselves to their peers, industrial companies can unveil critical insights and approaches taken by others – which can help ensure the successful deployment of AI in support of business objectives such as competitive excellence.

Through this research into what defines Industrial AI leadership, ARC has determined that leaders:

Invest in building in-house AI expertise.

Govern data and AI with highly inclusive global multi-disciplinary teams.

Use Governance Councils to ensure easy access to AI investment funding.

Prioritize AI use cases with fast time to value.

Invest in Industrial use cases across their whole value chain.

Consider data quality their greatest technical challenge.

Invest in Industrial (Grade) Data Fabrics.

Implementing Artificial Intelligence can be a daunting task, but with the right strategies and approaches manufacturers can increase their odds of successfully implementing AI into their operations. Based on ARC research analysis, here are our summarized recommendations to become an Industrial AI leader rather than a laggard:

Build in-house expertise with an Industrial AI Center of Excellence (CoE).

Have your Industrial CoE develop Industrial Automation and Software partnerships.

Create a Governance Council for ethical and inclusive AI.

Make AI a dedicated budget item.

Invest in data quality with Industrial (Grade) Data Fabrics.

Prioritize Industrial AI use cases with fast time to value.

Leverage your Enterprise Software Vendors investments in AI.

Process, discrete, and hybrid manufacturing companies often seek to compare themselves to other companies that are in some ways like themselves. They want to better understand their relative performance in a particular area, such as using innovative new technology. Are they ahead of the curve, at the bleeding edge of technology adoption? Or are they way behind the rest of the pack?

To shed some light on this, ARC undertakes a series of timely, topical primary research projects among industrial end-users. In these projects, ARC first conducts an online survey of industrial end users to learn about their organization’s usage and adoption of initiatives and technologies related to the topic at hand.

ARC then splits the responses into three groups – Leaders, Mainstream, and Laggards – based on a set of targeted performance assessment questions included in the survey. These groups correlate to how well the responses match ARC’s prior expectations about how leaders in the space will perform, which can be informed by additional research, analysis, or maturity assessment. In most cases leaders will make up 15-25 percent of the responses, laggards will also make up 15-25 percent, and the mainstream group makes up the rest, typically 50-60 percent. These groups are then compared in various ways based on responses to the survey questions. The results are analyzed and described in a report such as this one and made available to certain ARC clients.

Based on demand from industrial organizations and their automation and software suppliers, and their collective concerns that AI has the potential to expand an already significant digital divide, the first ARC Technology Leadership Report focuses on the Industrial AI (R)Evolution.

For this report, ARC conducted an online survey in October 2023. A total of 525 respondents participated. The respondents were end users with influence/decision making power and/ or knowledge of their industrial organizations usage and adoption of Artificial Intelligence (AI) initiatives and technologies. See the appendix for detailed demographics of the survey participants.

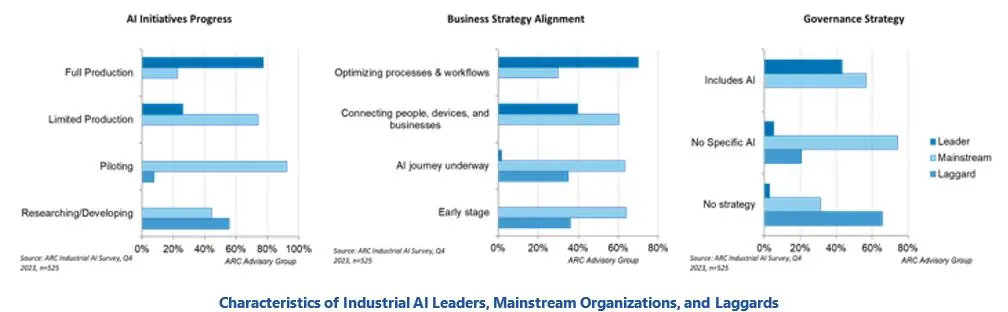

Industrial AI leaders performed well in three areas investigated by ARC. This framework was used to split the responses into three groups:

Industrial AI Progress. How far has the company progressed in deploying Artificial Intelligence Initiatives/Technologies?

Strategic Alignment. How well does the company’s AI strategy align with the overall business strategy?

Governance. How robust and inclusive is the company’s AI governance strategy?

Throughout this report we share high level insights into the characteristics of those organizations that are leading the Industrial AI (R)Evolution, quantify that leadership across 25 Industrial AI use cases, and make specific recommendations on how laggards can try to cross the AI digital divide to remain competitive.

Beyond what we can share in a single ARC Report, ARC clients are encouraged to reach out to ARC Analysts to get deeper insights into what leaders are doing in their particular industry, and get tailored recommendations for their specific digital transformation journey including how to leverage AI.

A demarcation is evident between those who have a dedicated AI budget and those who don’t. Leaders tend to have a budget and prioritize investments in specialized hardware and infrastructure, software and tools, and funding for scaling AI initiatives and expansion into new use cases. Many digital transformation initiatives, including AI projects, are hampered by a mismatch between the project scope and the budget. This occurs when resources allocated for the project are not sufficient to meet its requirements, leading to a lack of progress, delays, and project failure. Additionally, when the budget is limited, the project team may be forced to cut corners and make sacrifices, compromising the quality and functionality of the solution – not something that’s recommended for any industrial grade project, but especially not for AI use cases where worker and public safety could be impacted by lower fidelity results.

Productivity and increased quality are at the very core of manufacturing and industrial operations. Catalyzing it and extracting even more of it has long been the cornerstone conversation amongst operational leaders. Therefore, it comes as no surprise that ALL respondents see these as the critical areas where AI must deliver measurable improvement. It’s also a reminder that industrial organizations have been applying AI techniques to achieve these performance improvements - for more than a decade, in the case of leaders. What separates the leaders from the others, however, is their ability to innovate faster and identify increased revenue from existing AI programs, and by adding Generative AI to their Industrial AI toolset. Easier access to AI budgets is one factor that is helping leaders move further ahead of the mainstream and laggards.

AI is empowering companies to innovate at an unprecedented pace, revolutionizing traditional business models and processes. By leveraging AI, organizations can automate routine tasks, analyze vast datasets, and derive actionable insights with remarkable speed and accuracy. This acceleration enables companies to make informed decisions swiftly, respond to market trends in real-time, and identify new opportunities for growth. AI’s predictive capabilities allow businesses to anticipate new or modified product offerings and optimize supply chains. Additionally, AI-driven automation streamlines workflows, freeing up human resources to focus on more creative and strategic endeavors.

The incorporation of AI not only expedites innovation but also significantly contributes to revenue growth. By leveraging AI-driven analytics, companies can identify untapped market segments and fin-tune their product offerings. Moreover, the automation of routine tasks on the manufacturing floor reduces operational costs and improves overall efficiency.

Easier access to AI funding doesn’t guarantee success. There is a close relationship between the success of AI projects and the recognition of the importance of internal collaboration. When the leaders are examined, it becomes clear many of the respondents cite dross divisional collaboration to be important or very important to the success of their projects.

Embarking on implementing any transformative technology is a complex endeavor that transcends the boundaries of individual divisions within an organization. To succeed in implementing AI projects, organizations must collaborate across multiple divisions. This imperative arises from the intertwined nature of modern business functions, where siloed efforts can lead to inefficiencies and missed opportunities. Collaboration facilitates the alignment of goals, strategies, and resources, ensuring a cohesive approach. Different divisions bring unique expertise and perspectives to the table, allowing for a comprehensive understanding of the organization’s current state and future objectives. For example, successful collaboration between IT (information technology) and OT (operations technology) departments can bring together IT’s expertise around network infrastructure, cybersecurity, and software applications with OT’s specialization in hardware and control systems around machinery and production processes. Engineering Technology (ET) departments have much to learn from their customers usage and failures of their products, and from their OT counterparts on the operability and maintainability of their plant designs, and the manufacturability of their product designs. Cross-divisional and cross-functional collaboration not only fosters a culture of innovation, but a higher likelihood of achieving success with AI.

Executive Overview

ARC Technology Leadership Report Methodology

Analysis – Characteristics of Leaders

The Digital Divide Grows in Industrial AI Use Cases

Best Practices in Industrial AI

Recommendations for Closing the AI Digital Divide

Appendix

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

Learn new ideas, establish valuable relationships, and refine your company's strategy at ARC’s Upcoming Forums.