A lot is being written regarding Internet of Things (IoT), Industrial Internet of Things (IIoT) and Industry 4.0 or Manufacturing 4.0 concepts by organizations worldwide. Here we define them, and position the associations.

The Internet of things (IoT) involves a network of physical devices (like vehicles, home appliances and industrial equipment) having embedded electronics, software, and networking. This IoT technology enables them to connect and exchange data with cloud applications and other devices. Each device has a uniquely identifiable Internet address, and can interoperate using the available Internet infrastructure.

Your smartphone represents a common example in use today that we are familiar with. The phone is an intelligent device that sends data (like GPS location) to applications in the cloud (mapping). The cloud application performs a function, and send results back to your phone (your location and directions to where you want to go).

Consumer electronics – particularly smartphones – provided economies of scale and infrastructure that lowered the costs of sensors, networking, cloud computing and application development. Other consumer IoT products include wearable fitness trackers, smart thermostats, connected cars, and many other product categories. This cost advantage and proven platforms combined with high business benefit drives the current rapid IoT adoption.

IoT with internet communications provides a huge improvement over machine-to-machine (M2M) in terms of both bandwidth and quantity of connections. M2M uses point-to-point communications usually with cellular or dial-up technologies.

Consumer IoT is driven by the sometimes-fickle interests of individuals, and can have fad-like buying patterns. Industrial IoT is much different, and involves approval by decision makers who require a clear benefit and corresponding business case. Frequently, a sponsor or “recommender” investigates, determines how the benefit will be derived, and includes IIoT in a proposal. Management reviews and either approves or denies the project. This leads to a rational, business-driven decision. Industrial IoT involves projects with clear business benefits.

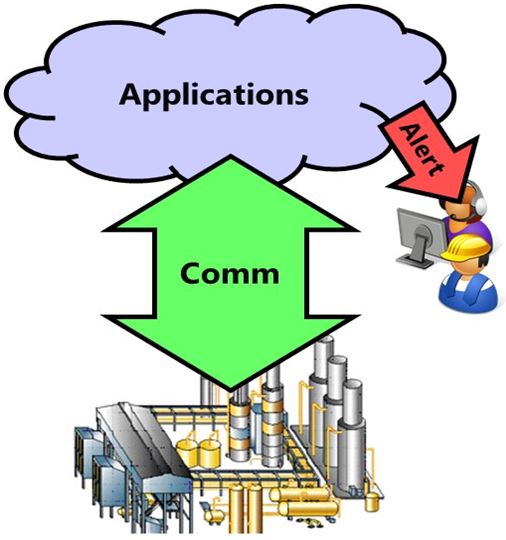

The architecture for IIoT can be simplified into three major components:

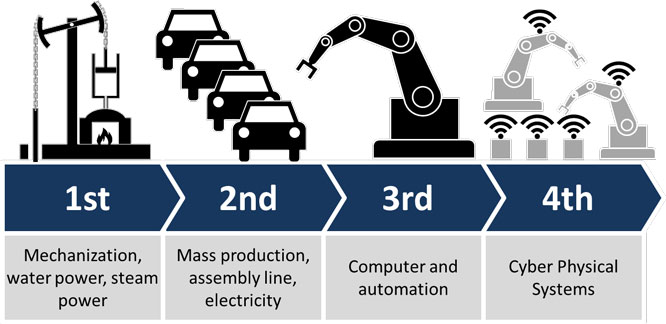

The Industry 4.0 concept focuses more on enterprise-wide business process automation which can create a "smart factory". Industry 4.0 also allows for the development of new business models which may contribute to radically new ways of interaction across the whole value chain.

The term "Industrie 4.0" originated with a program of the German government which promotes the computerization of manufacturing. The characteristics given for the German government's Industry 4.0 strategy are the extensive customization of products under the conditions of highly flexible mass-production. The associated automation technology utilizes methods of self-optimization, self-configuration, self-diagnosis, cognition and intelligent support of workers in their increasingly complex work.

The origin of the term Industrial IoT was more of an enabling technology for digital transformation. While industry 4.0 was more focused on the aspects of digital transformation. Today, there is a lot of overlap with IIoT more commonly used in the Americas, and Industry 4.0 in Europe.