a turnout of over 300+ delegates. AVEVA participated as a Gold Sponsor at the Forum and in the session on Digital Transformation and Sustainability Initiatives (Part 2), Satyendra Dubey, Principal Consultant, Value Chain Optimization, APAC, AVEVA shared his insights on sustainability and decarbonization that he had gathered from his interactions with clients in the APAC region. His presentation was on how to repurpose and revitalize your digital landscape, leading to transformation and decarbonization. This blog captures the essence of his presentation; it can be viewed in entirety here.

a turnout of over 300+ delegates. AVEVA participated as a Gold Sponsor at the Forum and in the session on Digital Transformation and Sustainability Initiatives (Part 2), Satyendra Dubey, Principal Consultant, Value Chain Optimization, APAC, AVEVA shared his insights on sustainability and decarbonization that he had gathered from his interactions with clients in the APAC region. His presentation was on how to repurpose and revitalize your digital landscape, leading to transformation and decarbonization. This blog captures the essence of his presentation; it can be viewed in entirety here.

Satyendra’s presentation covered these interlinked factors:

While there are multiple pathways to achieve net zero emissions, the scenario is complex due to the dynamic interplay of market and regulatory environments, and the evolving technology landscape. When it comes to carbon pricing, Satyendra explained that there are a lot of initiatives and money involved, yet there’s uncertainty due to wide disparity in pricing across regions. The expectation is that the regions that have less or no carbon pricing will gradually move towards a pricing level that reflects a global mandate on decarbonization. For a technology to be successful, the demand and supply need to be finely tuned and next comes gauging the scale of adoption. A graph taken from a study by the International Energy Agency (IEA) illustrates that to meet 2030 emission targets, 80 percent of the technology is already available, and 15-16 percent is still to mature; but for meeting the 2050 targets the gap is large and companies are struggling to bridge that gap. Most companies today have adopted a three-phase approach to reach their targets: unlock efficiency (efficient operations, energy efficiency, recycling etc.), evolution (introducing low carbon emission components into the value chain, new feedstock, and upgrades) and net zero (involves major CapEx investments and even operating model changes). Further, Satyendra spoke about digital capability in the short and long terms that are required for successful transformation and decarbonization.

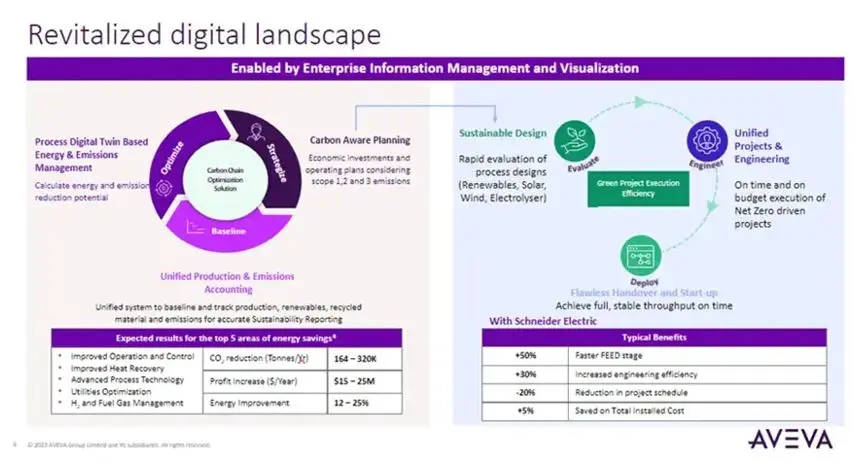

Short term: To unlock efficiencies and reduce carbon emissions you’ve to begin with the baseline, then optimize and strategize.

Long term: After strategizing on possible options, it has to be evaluated, engineered, and deployed.

Although a plant historian may be available, it just stores the data from the DCS without a structured repository of the entire organizational data. The APC is likely to have limited deployment and the entire planning process is challenging. The approach to the capital projects from design to final handover is document centric. Invariably issues arise and the time to full throughput gets extended.

In contrast, the revitalized scenario would have the capabilities and some of the same repurposed software to surmount those challenges. The production reporting and emissions accounting are unified and optimized with a process digital twin. On the planning side the application remains the same, but the Scope 1, 2 and 3 emissions can be configured, operational plans can be made, and investment decisions can be taken. This is the carbon chain optimization solution, wherein the economics can be evaluated and execution of net zero driven projects can be done on time and within the budget. Deployment is flawless and handover is done smoothly. The quantifiable benefits include 50 percent faster FEED stage, 30 percent increased engineering efficiency, 20 percent reduction in project schedule, and 5 percent saved on total installed cost. Further, Satyendra elaborated on each of the components and how they are all interlinked. For example, with repurposed software for carbon calculations, a unified report can be generated about the production facility and emissions; and this will facilitate adherence to mandatory regulatory norms.

There are three energy efficiency opportunities:

Best practice minimum: Can be delivered through APC optimization, energy performance management, etc.

CapEx minimum: Takes a longer time and requires focused research and evaluation.

Thermodynamic minimum: Based on R&D developments.

“The process digital twin is the key to capturing the best practice minimum,” said Satyendra. But first three gaps have to be overcome: variability, optimal target, and operations and maintenance. All these can be enabled and supported by a digital twin of the facility.

Industry is trying to move away from current gray operations to greener alternatives. Optimized plans are made to evaluate decarbonization alternatives (feedstocks, operation, intermediates and product slate). A system of enterprise information management and visualization can be added to the current system to revitalize and track current emissions and generate a decarbonization roadmap and put it on the management dashboards. This will enable companies to track initiatives, projects and report on sustainability aspects.

Unified production and emission management for a petrochemical plant: AVEVA’s Production Accounting solution reduced total loss (including from emissions) by 50 percent and CO2 was reduced by 10,600+ tons per year.

Site wide optimization for a refinery: AVEVA’s Process Optimization solution and PI Vision reduced energy usage and CO2 emission; and ROI was realized in less than 6 months.

Carbon aware planning for global oil major: AVEVA’s Unified Supply Chain solution helped to evaluate future projects and determine their decarbonization path across their plants. This solution enabled visibility and control across their projects.

Unified engineering for a new project by oil major: AVEVA’s full portfolio of the Unified Engineering solution reduced engineering man hours by 50 percent.

AVEVA has the required architecture and expertise to be your partner on the digital transformation and decarbonization journey.