Keywords: Ansible, Industrial Software, Open Source, OpenShift, Red Hat, RHEL, ARC Advisory Group.

With the overwhelming success of open source software in IT, end users and software suppliers (especially Linux distributors)  now see operational technology (OT) applications as suitable areas for deploying advanced IT rather than traditional proprietary full stack software solutions. To achieve this within industrial manufacturing environments, IT software suppliers must adapt their solutions to the requirements and characteristics of the industrial edge; especially high reliability and predictable performance when running on endpoints with limited resources. Through decades of experience and collaboration on Linux, companies such as Red Hat are extending the reach of modern software into these new areas.

now see operational technology (OT) applications as suitable areas for deploying advanced IT rather than traditional proprietary full stack software solutions. To achieve this within industrial manufacturing environments, IT software suppliers must adapt their solutions to the requirements and characteristics of the industrial edge; especially high reliability and predictable performance when running on endpoints with limited resources. Through decades of experience and collaboration on Linux, companies such as Red Hat are extending the reach of modern software into these new areas.

If “software is eating the world” then most of the eating is being done by open source software. The success and prevalence of open source today has both technical and business roots. From a technology standpoint, modern software development and collaboration tools enable global teams from different firms to create and successfully manage software projects of high complexity. Examples of such projects are the Linux OS, Docker, the KVM Hypervisor, Kubernetes, Python, Java, Ansible, Apache, and many, many others. From a business standpoint, using open source enables firms to leverage vast amounts of high-quality software developed by others and to focus their (always limited) software development resources on projects that will differentiate and drive their specific business.

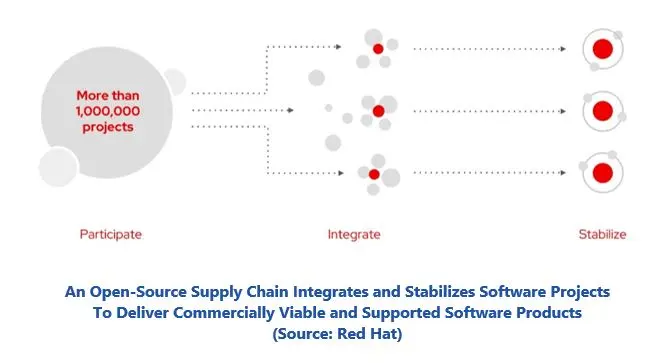

Yet businesses of all sizes confront issues when using open source software. While the technology is powerful, the means of delivery and the lack of support represent a barrier to most firms. The software end user faces a highly fragmented and bewildering array of dozens of open source foundations supporting thousands of interdependent software projects, with widely varying levels of activity, installed base, and documentation. Going to GitHub, downloading, building, and deploying pure open source code is possible, but is obviously not a viable long-term option for firms that must deliver effective long-term support for all the software they deliver to their customers. Rather, what has emerged is a set of firms that leverage numerous open source projects and deliver branded and integrated commercial software products with well-defined levels of performance, documentation, and long-term support.

These firms do more than deliver a distribution of selected open source software, although they are often described simply as “distributors.” In addition to distributing, these firms add significant value by adding capabilities and features that provide ease of use, integrations with other software and services, tiered levels of end user support, and complete product life cycle management. Through their operations they transform open source projects into fully acceptable, supported, commercial products. Red Hat is the largest example of such a company, but there are many other firms that specialize in different areas of IT and open source. The important point is that these companies commercialize sets of open source projects in ways that make the resulting products more useful, acceptable, and valuable for commercial customers.

This new software supply chain is now extending from IT into the operational technology (OT) software space. Traditionally OT software has been specialized and quite distinct from the IT realm, but as the capabilities of IT have expanded to include systems and services with very high availability, low latency, and scalability, IT solutions with these characteristics (which are those of the cloud computing environment) are now penetrating OT industrial applications all the way to the enterprise edge, including industrial automation applications in the factory and plant. This new penetration of IT software is a sea change for manufacturing end users and established automation suppliers alike.

Industrial automation suppliers have been accustomed to developing and delivering industrial automation solutions based on dedicated function hardware appliances (PLCs, DCS controllers) with a software stack that is also fully dedicated to industrial automation. In earlier times when IT lacked any such ability, their engineering expertise and experience enabled them to deliver the high availability and predictable performance that industrial automation demands. But today, with the penetration of IT software into industrial automation, these requirements can be met, and the value of existing solutions can be surpassed through the use of more modern software technologies, most of which originate in open source.

Automation suppliers now face the challenge of choosing new partners for both hardware and software who can deliver platforms with the required performance metrics and can support them over a complete lifecycle. The era when suppliers could “build everything in-house” has long passed. Instead, suppliers are searching for platforms on which they can run their existing applications and (more importantly) deliver new and better industrial automation capabilities -- delivered through effective industrial application of powerful IT.

From the perspective of the automation industry, this new software supply chain offers several advantages. Software partners  can offer them a solid multi-year product roadmap, support, training, consulting, greater software security, and opportunities to collaborate in development. It should improve the focus and productivity of their own software development. It avoids the risks of “do-it-yourself” or “science project” program developments based on open source. For example, pilot projects with customized Linux builds using Yocto require a serious vendor commitment to the underlying project (Yocto) if they are to be commercialized. By contrast, almost any level of support can be found in the market for commercial Linux distributions. Another major benefit is management of the software’s provenance and supply chain security, an increasingly challenging task which do-it-yourselfers overlook.

can offer them a solid multi-year product roadmap, support, training, consulting, greater software security, and opportunities to collaborate in development. It should improve the focus and productivity of their own software development. It avoids the risks of “do-it-yourself” or “science project” program developments based on open source. For example, pilot projects with customized Linux builds using Yocto require a serious vendor commitment to the underlying project (Yocto) if they are to be commercialized. By contrast, almost any level of support can be found in the market for commercial Linux distributions. Another major benefit is management of the software’s provenance and supply chain security, an increasingly challenging task which do-it-yourselfers overlook.

Automation suppliers are not deeply familiar with software technologies like virtualization, containers, Linux kernels, Kubernetes, etc. Launching into this realm feels somewhat like taking a dive into water of unknown depth and temperature. One has little idea what to expect. What evidence is there that success is likely? There is strong evidence, but it is not always well known or well publicized. To illustrate, let’s drill down into the history of collaboration between Intel and Red Hat.

Intel's X86 architecture has been employed in both IT and industrial applications for decades. In IT servers and data centers much of the success of X86 derives from its superior support for virtualization. For years Intel has been very active in open source software, especially with respect to Linux, and has also collaborated deeply with server OEMs to maintain the high performance and strong preference for X86 in cloud computing and data centers. Intel and Red Hat, respectively, are the two largest contributors to Linux. Thus, Red Hat and Intel have a decades-long history of open source software collaboration.

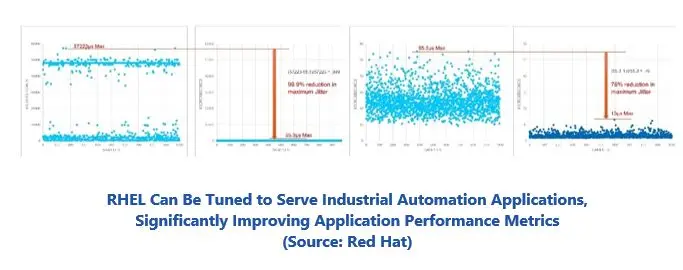

For the past few years, this collaboration has grown and extended further into industrial applications, culminating in the recent development of an industrial edge platform. Intel worked with Red Hat to tune Red Hat Enterprise Linux (RHEL) to take advantage of Intel’s built-in hardware capabilities like real-time compute. As such, Red Hat has developed Red Hat Enterprise Linux for Real Time not only to support constrained hardware for smaller edge device deployments, but also as a foundation for technologies enabling modern approaches to building and operating industrial automation into the broader context of the industrial edge platform. With a combination of well-tuned hardware and suitable software, critical industrial performance metrics such as latency and jitter improve by orders of magnitude compared with general-purpose off-the-shelf configurations (see figure).

Besides tuning Intel hardware for industrial endpoints, Red Hat has developed RHEL to support diverse computing architectures and software configurations that are optimized for mixtures of containerized and conventional applications. These are especially well suited for industrial endpoints such as virtual PLCs, which may run multiple applications but where the PLC application is the most critical.

As a company with a 30-year history, Red Hat is steeped in experience with Linux and numerous other open source projects. Red Hat’s business model is based on open source code, community software development, software quality assurance, and professional support. Commercially, Red Hat provides support, training, integration services, and consulting to their customers. Such support includes long product lifecycles, reliable periodic updates, dedicated software security teams, and a large ecosystem of partners.

Red Hat’s product portfolio, which forms the foundation of their industrial edge platform, revolves around three major components:

Red Hat Enterprise Linux (RHEL): The firm’s commercial Linux distribution, Red Hat Enterprise Linux provides a consistent, flexible, and security-focused foundation that delivers remote management, customizable image generation, and staged update with intelligent rollbacks to maximize the stability of application deployments at the edge. As a source of safe and reliable Linux innovation that makes industrial automation successful, RHEL can be deployed across multiple hardware platforms such as servers, workstations, and edge devices.

Red Hat OpenShift is a hybrid cloud application platform for building, deploying, and running applications consistently across different environments, including public cloud, data centers and the edge. Built on a foundation of RHEL, OpenShift is a comprehensive application platform with out-of-the-box developer tools, continuous integration (CI)/continuous delivery (CD), and security capabilities, allowing customers to focus on application development and delivering results.

Red Hat Ansible Automation Platform - Often described as “infrastructure as code,” Ansible is an open source configuration management tool that automates the provision and configuration of storage, servers, networking, applications, and workflows. The concept and practice of infrastructure as code (IaC) is 20 years old and widely deployed in IT, though sadly absent from the OT domain. Only now with the development of more open and advanced industrial automation is IaC technology able to address OT and small industrial devices.

Red Hat Device Edge was introduced in 2022. Red Hat Device Edge is a combination of three products, including RHEL, Ansible, and Red Hat build of MicroShift (a lightweight Kubernetes derived from OpenShift). Each of these is optimized to manage industrial edge endpoints at scale. While Red Hat Device Edge has many applications, some example industrial use cases are industrial PCs, industrial automation controllers, AGVs, industrial ML/AI, mobile robots, and HMIs. These industrial edge endpoints are characteristically heterogeneous, have limited resources for compute, storage, and networking, and often execute critical applications.

In practice, industrial edge endpoints execute some combination of applications on bare metal, virtual machines, or containers. To facilitate ease of hardware and software modular integration, the industrial edge platform is grounded in open standards and propelled by open source innovation. Red Hat Device Edge provides different execution environments that can support, manage, and automate any of these installations.

Automation suppliers should now evaluate IT and open source software firms for inclusion in their software supply chain. Adding such firms is an important strategic option that can transform many software infrastructure issues from in-house problems to mature, IT-oriented solutions.

In choosing suppliers/partners, pay attention to factors such as their track record, support policies, product breadth, product roadmap, ability to adopt emerging technologies, and commitment to industrial markets.

Be sure to understand supplier business models, differentiation, and potential areas at risk of vendor lock-in.

Manufacturing end users should understand incumbent supplier strategies for adopting modern IT software within their OT environments and engage directly with their own IT organizations to learn how these technologies are already used in-house.

Manufacturers and suppliers should both evaluate the opportunity to leverage IT automation (IaC) to manage their industrial equipment and endpoints. It has potential to relieve their technical workloads and improve service levels, including responses to cyber security threats.

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

Obtain more ARC In-depth Research at Market Analysis