Keywords: Software Defined Automation, SDA, Industrial DevOps, PLC Engineering Process, ARC Advisory Group.

Information technology (IT) has had a growing influence on operations technology (OT) for nearly a decade. For industrial automation, it is more of an evolution than a revolution in which automation systems are migrating to open architectures and virtualized deployment. Suppliers are now introducing virtual PLCs and creating a path to completely virtualized solutions in the  future, but industrial machines have long lifecycles, so physical and virtual PLCs will exist side by side for a long time.

future, but industrial machines have long lifecycles, so physical and virtual PLCs will exist side by side for a long time.

The key to the success of software defined automation will not be virtualized controllers, but rather the tools and environment in which they are deployed. This is the opportunity for the market to rethink the PLC engineering process, from software development to the automated orchestration of whole fleets of PLCs. However, the development is still in an early stage as vendors focus on solutions for their own products rather than seeing the big picture.

One bright light in this new era is the start-up called Software Defined Automation (SDA) – named literally for what the company does. SDA is pioneering the concept of Industrial DevOps, which brings IT best practices for development and operations to industrial automation.

As automation systems become more software-defined, there will be consequences for machine builders, equipment providers and end users. While many already use virtual machines to deploy non-critical software for Level 3 and 4 tasks, developing, deploying and managing time-critical control applications virtually is completely new terrain.

Ideally, a factory would use PLCs from a single vendor, all programmed in the same language according to a standardized structure. But the reality is different: automation engineers today often manage PLC code in different versions of the same vendor’s engineering software, which may be incompatible. Also, poorly documented legacy code can be tough to modify or troubleshoot. On top of that, manufacturers have difficulty hiring and training young engineers willing to use engineering tools and programming languages that date back decades. The engineering process is hindered by the absence of common tools for versioning, backup, user management, remote access, connectivity, and security. Vendors may offer these features, but they usually only work with the vendor’s own system. In a multi-vendor environment, the result is operational inefficiencies, security risks, increased downtime, and higher lifecycle costs.

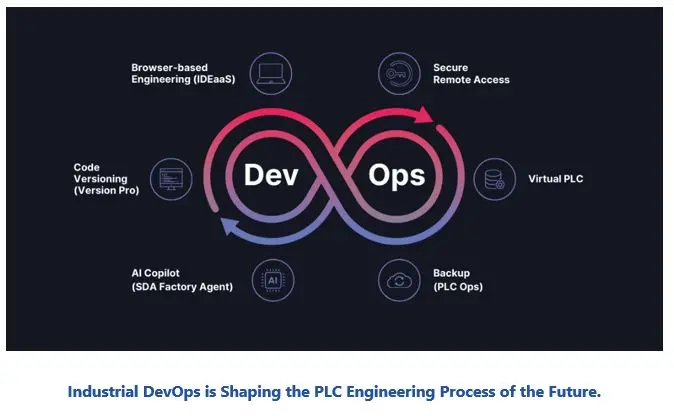

Industrial DevOps extends both the “development” and the “operations” part of DevOps to industrial systems. Industrial DevOps tools support emerging best practices for orchestrating both new and legacy PLC systems programmed in a variety of languages in a vendor-neutral framework – a key element that has been missing so far. As the popularity of software defined automation grows, users will need vendor independent tools to manage their growing fleets of automation systems and devices in both factory and process automation. The benefit of using Industrial DevOps is likely to be a reduction in mean-time-to-repair (MTTR) and ultimately improved factory uptime.

The IT world relies on standards to eliminate competing technologies and allow innovation to move on to new challenges (Imagine if there were still competition for Ethernet!). In OT, the pace of change is much slower because the emphasis is on minimizing risk. Investments in manufacturing equipment are amortized over years and even decades, and processes often need to run around the clock to generate continuous profits. Industrial users tend to be tribal and stick to one vendor’s technology, so there is little incentive for industry-wide initiatives to take root.

Automation solutions traditionally consist of mostly bug-free code running on isolated devices. Code changes are unwelcome because of the risk of interrupting the process, and functionality updates are rare unless equipment is upgraded or expanded. But times are changing. Today’s factories are re-programmed more frequently, so more flexibility is needed to keep costs in check and to avoid downtime. Manufacturers are also under pressure to ramp-up new production facilities faster to adapt more quickly to changing demand (think of rapid vaccine production). Oddly enough, manufacturers are still ignoring the huge potential of reducing the risk of downtime due to lack of automated backups, coding errors or use of USB sticks (often the source of ransomware attacks).

The traditional PLC engineering process has a lot of room for improvement and will benefit from Industrial DevOps. Inconsistent version control and manual code management increase the risks of operational errors, downtime, and security breaches. Many installed systems have inadequate disaster recovery capabilities, and insufficient security measures in PLC management pose significant threats. To meet these challenges, the entire PLC engineering process needs to work more like in the IT world.

SDA is the first vendor to offer a solution for seamless and secure PLC management across multiple vendor platforms. The company’s Backup and Version Pro allows users to manage PLC code from different automation vendors with automated backups and robust version control. While existing engineering tools may offer these features, SDA’s solution manages these tasks with just one tool for multiple PLC brands and models. Using a browser, users can keep a record of project changes, compare versions side by side, and understand what was changed, when and by whom. The solution also offers automated backups and disaster recovery strategies that protect against data loss and operational disruptions and can reduce mean time to recover. In addition, Backup and Version Pro offers Secure Remote Access, as well as fine-grained user management features such as time and role-based user management for PLCs and projects.

PLCs may stay in operation for decades, so legacy code can become a problem if it is not well documented. SDA’s Factory Agent is an AI-assisted copilot that translates legacy code into human language and back, allowing even non-PLC developers to quickly understand a function. This can help manufacturers keep specific knowledge in-house even as generations of PLC programmers retire. Factory Agent can also help users compare versions of code by picking out and explaining differences in plain language. This solution is available currently for installed PLCs and will help users smooth their transition to virtual PLCs.

After decades of little development in PLC technology, automation systems today are evolving into IT systems as more and more functionality is defined in software. Legacy PLC systems are being integrated with IT at the industrial edge, while new software-defined controllers are emerging, ready to take their place in a modern IT architecture. To manage these systems requires vendor-neutral tools to develop cross-platform software, automatically deploy controllers and devices, and manage them with the professionality and consistency of IT assets.

As users look to the future and navigate a path through these new developments, it’s worth looking at the solutions for Industrial DevOps pioneered by SDA. The company may still be in the start-up phase, but its solutions are already shaping the PLC engineering process of the future.

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

Obtain more ARC In-depth Research at Market Analysis