Yokogawa Engineering Asia participated as a Gold Sponsor at the online annual ARC Industry Forum Asia titled Accelerating Industrial Digital Transformation and Sustainability on July 12-14, 2022. This Forum saw registrations of 1,600+ delegates for the two language tracks – Japanese and English. In the session on Digital Transformation Initiatives, Yokogawa Engineering Asia’s presentation was interestingly titled “Cracking the Code for Digital Transformation – Smart Manufacturing.” The focus was on the company’s vision of “Industrial Automation to Industrial Autonomy (IA2IA)” and how the company’s solutions are helping others on their digital transformation journey.

At the end of this session there was a lively panel discussion. This blog captures the key points of the presentation and Yokogawa Engineering Asia’s views at the panel discussion. The entire session can be watched on YouTube.

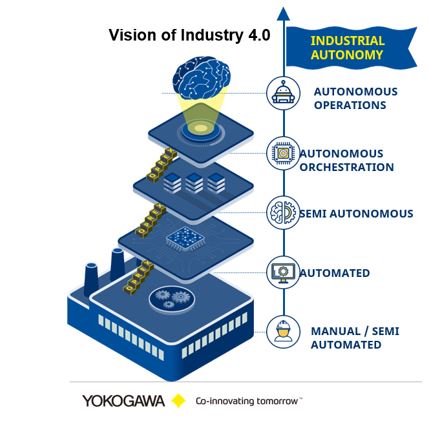

For years the buzzword across industries has been digital transformation/Industry 4.0. This mimics Yokogawa’s vision of “Industrial Automation to Industrial Autonomy (IA2IA).” Every organization is at a different level of maturity – manual/semi-automated, automated etc. finally leading to the ultimate objective of Industry 4.0 – Industrial Autonomy. Organizations need to understand the current status, where they are on the digital transformation journey, and how to actually get there.

For years the buzzword across industries has been digital transformation/Industry 4.0. This mimics Yokogawa’s vision of “Industrial Automation to Industrial Autonomy (IA2IA).” Every organization is at a different level of maturity – manual/semi-automated, automated etc. finally leading to the ultimate objective of Industry 4.0 – Industrial Autonomy. Organizations need to understand the current status, where they are on the digital transformation journey, and how to actually get there.

As a partner of the World Economic Forum (WEF), Yokogawa provides digital transformation programs customized for their clients. Yokogawa has signed up for the Global Smart Industrial Readiness Index Initiative (SIRI) that provides a methodology to understand where companies are, benchmark against industry peers, and work towards getting there. This assessment is done via SIRI/tier technology in three tiers:

This approach helps identify the gaps and opportunities to accelerate the digital transformation journey. Further, the 16 dimensions of self-evaluation based on the SIRI framework was explained. The digital transformation journey is a multi-year phased approach. It has to be an interactive approach with the customer. After each phase you must reassess, refine, and realign.

For a customer in the edible oil space in Southeast Asia, the SIRI assessment helped identify the business and operation KPIs, cost drivers, and challenges. The key challenges lie in knowledge retention and attracting young talent and ensuring that they scale up quickly. The assessment identified the gaps, and these gaps are seen across other industries too:

Digital transformation comprises of three distinct phases: digitization (converting into a digital format), digitalization (making processes more automated), and digital transformation (integrating data and operations). So, after the assessment is made about the existing status and what the company wants to achieve, Yokogawa provides a best-of-breed solution roadmap.

Summarized below are Yokogawa Engineering Asia’s viewpoints during the lively panel discussion.

Project status and steps with reference to the customer in the edible oil business: Phase 1 is completed and now we are assessing what we have learned and providing the customer an updated execution methodology. Phase 1 was competed in 6 months and Phase 2 is likely to be completed in 9-12 months

Assessment as a practice for all plants or do you reach out to customers? Not as a practice because the interest and initiative should come from the customer. Often there is a management requirement for digital transformation to improve their business.

How digital transformation has helped Yokogawa’s growth in the last couple of years: The COVID-19 situation was unexpected, but it accelerated the demand for digital transformation. Yokogawa invested heavily in consulting and looked deeper into the SIRI framework and developed its own assessment areas. We also started looking at robotics and integrating systems on a single platform.

Level of adoption (of the assessment matrix) in the industry and Yokogawa’s experience: The consulting program began before COVID struck and after that it speeded up. The lower industrial tiers evinced interest in the assessment – where they are and where they could reach. Surprisingly, none of the companies wanted to reach Level 5 (total autonomy) – because people still want some degree of control. Most companies already have some kind of assessment being done, but there is still a “wait and watch” attitude.

Role of open-source in industrial digital transformation: In terms of technology open-source is a great concept, but at the end of the day ownership also plays an important role. Digital transformation is not an end game, we need to continuously evolve and it must be scalable. And as open-source continuously develops and ties into what the industry requires it becomes the owner. So, you need to think hard before deploying open-source technology and try to grow with it.

Maturity assessment that addresses cybersecurity: Yokogawa assesses the current systems, the architecture in place, and the risk it’s likely to propagate. It defines the roadmap and what is going to be the future architecture. We assess (if already in place) or create policies and procedures that ensure cybersecurity.