The convergence of information technology (IT) and operations technology (OT) intensifies daily. In the long run, this trend will forever transform automation architectures as we know them. So far, it has resulted in the emergence of two concepts: the cloud and the edge. Each adds computing power to the automation process, either far away (cloud) or close by (edge). Are these concepts diametrically opposed, or do they go hand in hand? What are the tangible benefits for automation users?

In this Insight, ARC analysts Fabian Wanke, Florian Güldner, and David Humphrey consider questions about the cloud vs. edge and discuss their impact on automation architectures.

David: Traditional automation systems shunned modern computing technologies in favor of reliability, consistency, and familiarity; but the Industrial IoT is changing all that. End users realize that the next generation of productivity gains won’t come from a faster PLC, but rather from collecting and analyzing data from manufacturing processes.

Fabian: Back in 2017, I read an interesting article: "The Edge Will Eat the Cloud." This statement was provocative, but it is just as incorrect as if one would say that, in the future, all data will only be stored and processed centrally in a cloud, whether on premise or hosted.

Florian: The cloud adds functionality “on top” such as multi-site data analysis or complex AI algorithms. They run externally, either on premise or hosted by a third-party provider and thus don’t burden the automation system. The edge provides computing power locally, often right on the machine or along the production line. We are currently in a transition phase, so there is no clear path, and therefore see many different solutions. We also have the individual players to consider and their respective capabilities and strategies. These include suppliers, machine builders, integrators, and users. Dealing with brownfield installations is a completely different beast. My argument is that we must explore all available options, or “burn the candle at both ends” as much as possible right now to figure out what works for whom.

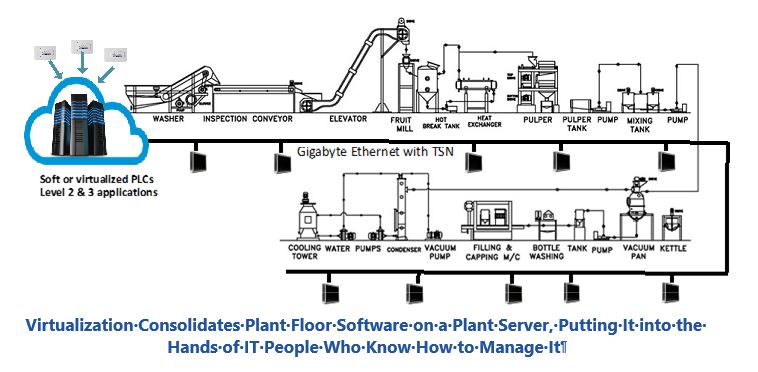

David: The soft PLC, which first emerged in the 1990s, was an early form of automation virtualization and proved that the PC is a viable automation platform. Today, virtualization can “clean up” and consolidate plant floor software by moving it to a common on-premise server. While this currently applies to level 2 and level 3 applications such as production management and process visualization, it is conceivable that - in the future - the control software could run centrally on a plant server. Current industrial networks already support closed-loop control and will soon benefit from standard gigabyte Ethernet with built-in determinism. Soon, 5G wireless technology will deliver even higher performance levels, but without all those cables.

Fabian: In the IT world, application software has run for years either on "bare metal systems" or on a virtual machine (VM). The first variant requires an operating system that has full control over the underlying hardware. The second option also requires an operating system, but with several operating systems sharing common hardware resources.

Florian: The main advantage of this form of virtualization is that it centralizes the software and entrusts its management to IT specialists who can ensure levels of quality of service or perform updates, ideally without disturbing running processes. Also, IT specialists can ensure system redundancy and backups in a way that was never possible with software delivered by the machine builder on a locally installed PC. So yes, users can certainly benefit, but there is a threat to others such as suppliers and OEMs, which could slow down the transformation.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Cloud, Edge, Automation Architectures, Industrial Networks, Predictive Maintenance, Industrial IoT, ARC Advisory Group.