ARC has been researching asset management for many years. It is a broad topic and we understand the challenges that organizations must overcome to maintain the integrity of their production assets. This guide can help you select the best asset integrity management solution to meet your needs..

The integrity of assets is high on the agenda of executives in manufacturing, energy. and every other enterprise where success depends upon complex equipment. They want top performance from all their facilities across a wide range of performance measures including revenue, safety, compliance, quality, energy, and operating costs. They also expect new facilities and major upgrades to be consistently delivered on budget and on schedule so that market opportunities can be exploited. Shareholders and regulators are no longer tolerating poor performance nor are they willing to accept risks. They expect excellence in all asset integrity management activities and want managers to immediately take the necessary actions.

ARC has been doing research in asset lifecycle management for over two decades. In the process, we have developed numerous reports and concepts that help organizations take control of their investments in capital equipment. Our model for asset lifecycle management is the culmination of those efforts and provides a useful platform for analyzing problems and developing strategies to achieve better performance from all capital asset investments. It identifies the key lifecycle stages and the processes that must be managed to ensure success. It also explains why critical interdependencies constrain performance and how collaboration and teamwork can be used to integrate activities and fully exploit the capabilities of a rich ecosystem of external stakeholders.

The following are a few of the strategic issues specifically covered in the Asset Integrity Management Software Selection Guide:

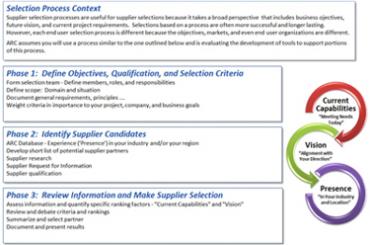

Careful evaluation of suppliers is necessary to ensure high quality, low costs, timely project completion, and minimum risk. However, it is never an easy task, especially when it comes to bigger projects in heavy process industries such as oil & gas. End users need to carefully develop the requirements that must be met to distinguish between the nice-to-have and must-have features of the project. Clear requirements are essential for any project.

The major driver behind asset integrity management initiatives is to ensure assets and infrastructure perform efficiently, optimally, and safely. Asset integrity management procedures and services, when properly planned, can help end users reduce capital expenditures, reduce operational expenditures, and maximize returns on investment (ROI) and assets (ROA). ARC is seeing owner-operators place increased emphasis on ROI and ROA in an effort to reduce both risk and costs. Furthermore, when it comes to convincing management of the value of asset management, nothing works better than demonstrated returns. Depending upon the process, industry, and operations, end users should try to quantify overall returns for AIM.

Limit Risks with Remote Condition Monitoring

Limit Risks with Remote Condition MonitoringRemote monitoring will not replace hands-on work performed on the plant floor or in the field. But it can reduce the time to respond, analyze, and remediate asset issues. Unscheduled downtime typically represents the costliest event in a plant. End users can reduce exposure to this risk through a combination of predictive and preventive maintenance activities.

This selection guide explores user objectives, business justification, application scope, selection criteria, and helps answer key selection questions. We understand the challenge companies have in selecting and implementing a solution. These include:

This ARC Selection Guide will help you select an asset integrity management solution for the future.

For more information on this technology guide or to discuss how we can help you, please contact us.