March 2-3, 2016 - Amsterdam, The Netherlands

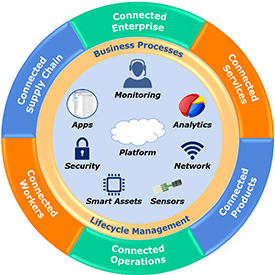

New and emerging IT technologies combined with innovative process technologies and product development, come together in innovative forms of physical manufacturing. This merger of technologies, such as the Internet of Things (IoT), industrial data analytics, machine learning, and new computing architectures with additive manufacturing or modular and mobile production, is supported by new electronic and informational processes. These initiatives are known as Industrial Internet of Things (IIoT), Industrie 4.0, Smart Manufacturing, etc. They have opened up the possibility for new business models, which can radically change the way industrial enterprises do business.

The business environment is increasingly dynamic and volatile. Companies face global and regional cycles of growth and recessions as well as rapid changes in regulations, energy and raw materials availability, markets, and competition. New business models, enabled by Connected Manufacturing, and Connected Supply Chain Networks, as well as leading edge technologies, will help companies remain competitive, and become leaner, agile, and more flexible.

The business environment is increasingly dynamic and volatile. Companies face global and regional cycles of growth and recessions as well as rapid changes in regulations, energy and raw materials availability, markets, and competition. New business models, enabled by Connected Manufacturing, and Connected Supply Chain Networks, as well as leading edge technologies, will help companies remain competitive, and become leaner, agile, and more flexible.

Information and automation technologies need to be implemented to boost productivity, flexibility, and responsiveness. They also introduce challenges such as cybersecurity and the convergence of operations and information technology (OT/IT). Processes that require little human intervention need systems that empower humans with the information they need, when they need it, so they can focus on problem solving and decision-making. Virtual collaborative workspaces will address organizational complexity, bridge distance, and facilitate remote intervention and mobility. Simulation and knowledge management systems help to preserve and develop know-how.

Process plants with continuous or hybrid manufacturing processes will leverage connected assets, combined with third-party services. Smart machines and equipment can support reliability, efficiency, and safety in plants by enabling predictive asset analytics. This will improve uptime and asset lifecycle performance or produce small batches of specialty materials. Production units will become modules, featuring ‘Plug&Produce’, enabling fast reconfiguration and optimization of production lines.

Discrete manufacturers will be able to produce customized products quickly and cost-efficiently. Soon, smart cyber-physical components communicate directly with machines, while background processes will trigger re-ordering and address potential deviations.

Which strategies can industrial enterprises adopt to position themselves, taking advantage of the latest technologies, while prioritizing their investments wisely? Join us at the Annual ARC Industry Forum Europe to learn from your peers how an information-driven strategy can position you to succeed and determine how to approach critical technology decisions.

Agenda

The schedule for the forum is as follows.

Wednesday, March 2

| 8:30 AM | Registration and Morning Coffee/Tea | |

| 9:00 AM | Welcome Address Uwe Grundmann, ARC How Megatrends Are Shaping the Future of Industry Florian Gueldner & David Humphrey, ARC |

|

| 9:15 AM |

Industry 4.0 in the Supply Chain of Arla Foods: Current PackML Case And Future Opportunities |

|

| 10:00 AM | Executing Engineering Projects at Kaneka Belgium Using Asset Information Management (AIM) Bert Van Baelen, Kaneka |

|

| 10:30 AM | Coffee/Tea Break | |

| 11:00 AM |

Workshop: |

Workshop: |

| 12:45 PM |

Lunch

|

|

| 1:45 PM |

Workshop: |

Workshop: Industry Experts: |

| 3:30 PM |

Coffee/Tea Break

|

|

| Smart Manufacturing, Machine Learning, and Analytics | Operations Management | |

| 4:00 PM | An IT Perspective on a Corporate Asset Management Implementation from Scratch to Perfection Edward van den Boogard, Huntsman |

Setting New Standards for MES at FrieslandCampina Chesse, Butter & Milkpowder |

| 4:45 PM |

Performance-based Digital Transformation |

Implementation of MES Quartis Optima in the Cosmetic Industry Denis Benoist, LVMH Fabrice Chausserais, Bodet Osys |

| 5:30 PM | ARC Wrap-up David Humphrey & Florian Gueldner, ARC |

|

| 6:30 PM | Evening Reception | |

| 6:45 PM | Networking Dinner | |

Thursday, March 3

| 8:00 AM | Registration and Morning Coffee/Tea | |

| 8:20 AM |

Welcome Address

Uwe Grundmann, ARC Improved Availability and Damage Avoidance at Water Treatment Plant Using Asset Analytics Speakers from FAG and Mitsubishi Electric |

|

| 8:50 AM |

Smart Manufacturing

Jan Snoeij, MESA |

|

| 9:30 AM | Customization and Mass Production Favored by New IoT-Enabled Economic Models Alessandro Bassi, Bassi Consulting |

|

| Open & Advanced Automation |

Industrie 4.0 & Industrial Internet of Things |

|

| 10:15 AM | How Open Standards Create the Soft Infrastructure for Industrie 4.0 Uwe Steinkrauss, OPC Eelco van der Wal, PLCopen |

Asset Analytics - Zero Surprises, Using Predictive Analytics to Improve Plant Performance Maurice Jilderda, Campione |

| 10:45 AM | Coffee/Tea Break | |

| 11:30 AM | Ubiquitous Data - Where May We Get? Johannes Kals, University of Ludwigshafen |

|

| 12:00 PM | Plenary Session Organization, Collaboration & Human Factors: 30 Years Experience - Is There an App for That? Maurice Wilkins, ISA |

|

| 12:30 PM | Lunch | |

| 1:30 PM |

Plenary Workshop: |

|

| 3:30 PM | Coffee/Tea Break | |

| 4:00 PM | Energy Optimization Thanks to Analytics and... People Bernard Flament, Prayon & Philippe Mack, PEPITe |

|

| 4:30 PM | ARC Wrap-up Florian Gueldner, ARC |

|

| 5:00 PM | Forum Ends | |

Location

The Forum is held at the Mercure Hotel Amsterdam City.

The Forum is held at the Mercure Hotel Amsterdam City.

Mercure Hotel Amsterdam City

Joan Muyskenweg 10

1096 CJ - Amsterdam

Netherlands

Phone (+31) 20 6658181

Fax (+31) 20 6948735

Email H1244@accor.com

www.mercure.com/1244

The Mercure Hotel Amsterdam City is set in a beautiful location by the river and provides easy access to the ArenA and the center of Amsterdam. Ample, enclosed parking is available and you can also reach the city center by public transport in just 10 minutes.