Knowledge Lens (a Rockwell Automation Company), participated as a Silver Sponsor at ARC Advisory Group’s 21st India Forum titled Driving Sustainability, Energy Transition, and Performance through Digitalization on July 12th and 13th, 2023. The 300+ delegates at the Forum networked, shared best practices, and got an overall view of market trends and requirements. In the Forum session on Industrial AI, Knowledge Lens’ customer Rajesh Lande, Senior General Manager, Dalmia Cement (Bharat) Group, spoke about how analytics and Artificial Intelligence power digital transformation have helped the company to achieve profitability and sustainability in manufacturing. When the customer speaks about how the supplier’s solutions have benefited and streamlined their operations it validates their claims.

At the end of the session, Ganesh H. Iyer, Chief Technology Officer, Knowledge Lens, joined him for the panel discussion. This blog captures the salient points of Rajesh’s presentation and summarizes Ganesh’s views. It can be watched in its entirety here.

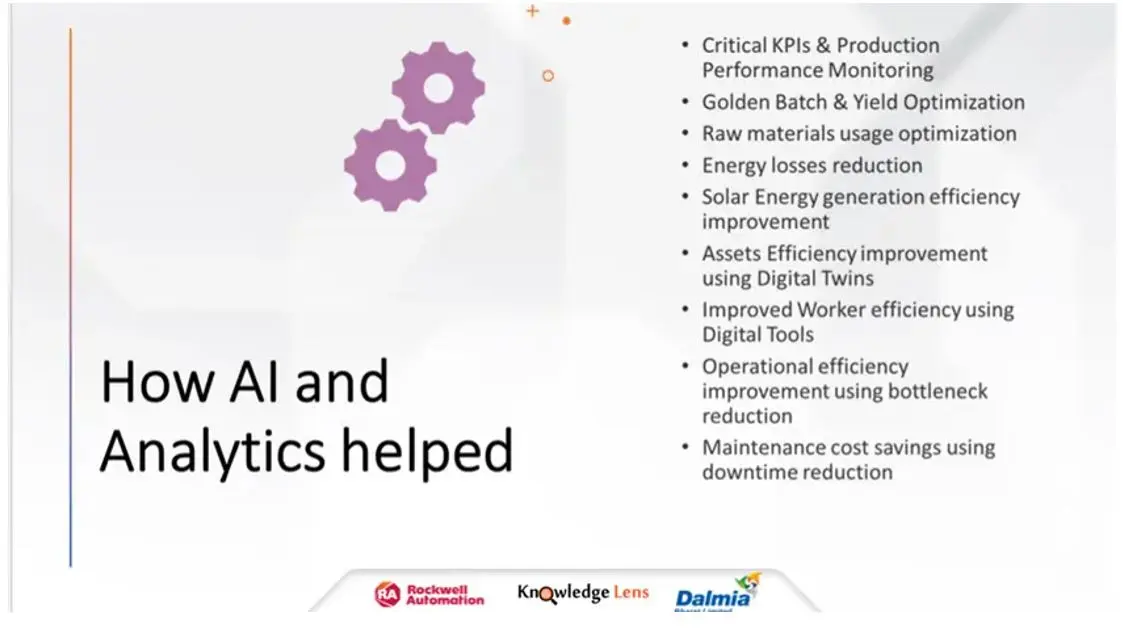

Across industries the business objectives are to improve productivity, optimize the investment made (add incremental revenue and generate new revenue), and ensure safety and work-life balance of employees. Rajesh provided insights into how the Dalmia Group implemented digital tools to improve manufacturing processes and power generation from their renewable energy source – solar plants as part of their cement production. The focus is now on renewable power generation. Digital interventions using AIoT (Artificial Intelligence of Things) are beneficial for the following areas: asset management, process management, energy management, and optimization. Knowledge Lens’ digital IoT Platform and solutions effectively focused on people, process, sustainability, utilities, energy, and raw materials and provided insights through Advanced Analytics & KPI Dashboards. The graphic below shows the key benefits of deploying AI and analytics.

Renewable energy has been introduced in Dalmia’s cement plants to reduce cost and contribute towards sustainability. Dalmia Cement (Bharat) Ltd. is the first cement company to join RE100 – a global collaborative initiative of the world’s most influential companies committed to 100 percent renewable power, led by The Climate Group in partnership with CDP (Carbon Disclosure Project). The company’s target is to achieve 100 percent renewable power by 2040; to date the company has already converted 26 percent of its conventional power to renewable power. Further, Rajesh spoke about how Digital Transformation led initiatives powered by IIoT and AI Platform & solutions provided by Knowledge Lens have facilitated centralized control, operational transparency, cost savings and improved worker efficiency.

Rajesh highlighted a few use cases of unique solar installations across Dalmia’s pan India cement plants. Solar installations, despite space constraints and in another which was used for water harvesting, are digitally monitored using advanced analytics and facilitated energy forecast generation and efficient usage. This helped in balancing their energy needs as part of their cement production. Next, Rajesh demonstrated the Insights, Dashboards, Proactive Alerts being monitored through iOS & Android-based mobile app for multiple levels for KPIs across Production, Power Generation, Waste Heat Recovery, Renewable Energy Generation, and various other areas of operation; and using the AI & IoT solution to monitor, manage and optimize inverter level and achieve efficiency in power generation.

The challenges are many:

Difficult to identify low power generating solar panel strings, leading to low power generation.

Large number of strings makes it nearly impossible to identify string-level inefficiencies.

Identifying panel-level defects and planning maintenance activities is very difficult.

Repeated cleaning activities whenever there is low generation.

Increased labor cost and excessive water utilization.

Knowledge Lens implemented AI & IoT Platform to calculate the energy loss via a root cause analysis enabled Models and operators/stakeholders received proactive alerts with information of when a panel was expected to reach a specified level of degradation. This helped to plan maintenance activities and improved profitability of the solar farm. The AI/ML Models within the solutions were used for energy generation forecasting and analysis.

Challenges:

Lack of real-time monitoring for critical process parameters.

Absence of real-time alerts for operators.

Difficulty in consolidating KPI dashboards for multi-plant operations under a single view for the plant corporate and management team.

Knowledge Lens deployed mobile app dashboards for KPI monitoring and remote monitoring of critical process parameters. The business value realized was huge: monitoring and proactive control, reduced operational risk by triggering alerts for deviations, enhanced worker productivity, and reduced downtime.

Knowledge Lens also helped to drive sustainability in emission reporting and forecasting by enabling Cloud DAHS for visibility across plants, simulating scenarios with a digital twin, carbon footprint monitoring, and so on.

During the panel discussion, Ganesh H. Iyer, Chief Technology Officer, Knowledge Lens, expressed his views. Responding to a question on Generative AI and large language models, Ganesh said that Microsoft works with partners and large industries to audit and give feedback so that there can be “fine tuning” of sensitive data. Azure and AWS offer options, such as starting with a pre-trained model that enables incremental fine tuning for specific datasets. This ensures that the data does not go out of the organization, but the knowledge comes in. To a query on facility management in an apartment complex, Ganesh explained that it is similar to monitoring utilities at a line plant, and the same solutions can be deployed effectively for asset tracking, energy consumption, water usage, and so on.

Knowledge Lens (a Rockwell Automation Company), a digital technology consulting and solutions provider, provides industrial artificial intelligence (AI), sustainability, and digital transformation solutions to manufacturers and enterprises across the world. Leveraging data science, analytics, and cloud, Knowledge Lens helps clients accelerate their journey towards autonomous manufacturing. Knowledge Lens offers AI-driven intelligent applications addressing manufacturers’ needs across the industrial lifecycle by unifying human and machine intelligence across edge to cloud driving sustainable business outcomes.