The primary purpose of remote condition monitoring of rail assets is to make a major contribution towards improving overall rail operations and performance in terms of reliability, safety, and efficiency. This innovation is driving maintenance of fixed and rolling stock infrastructure assets towards a ‘predict and prevent’ strategy by detecting early deterioration in asset condition thereby reducing the potential for service affecting failures. The key objective of remote infrastructure is to have a system that is capable of using the collected data to generate advisory information for operation team that will improve performance and safety, and ensures detailed maintenance works while still being cost effective.

In a highly competitive world, rail operations are heavily dependent on the condition of the asset. The rail transportation industry needs to strike a balance between growing operational costs, regulatory compliance, and safety standards while meeting objectives like punctuality, network speed, safety, and efficiency. Being a major asset and labor sector, railway networks are scattered over large topographies, and travel through inaccessible terrains with rough climatic conditions naturally makes the daily manual analysis and asset condition monitoring a cumbersome and expensive work.

Remote Condition Monitoring technologies through its potential to automate condition measurements and report asset failures of an asset have been helping the railroad industry to channelize their preventive maintenance and self-correction. The data gathered through remote monitoring has been a key driver of numerous asset maintenance decisions. It uses present and historical asset data to predict failures before they allow condition-based maintenance, which really reduces operating costs and improve productivity.

With a strategic approach to technology, information management and business process to deliver benefits in performance and long-term asset management, the remote condition monitoring makes it possible to monitor infrastructure assets such as wheels, points, track circuits, signaling systems, power supplies etc. The benefits result in avoiding delay minutes and saving millions of dollars for the rail operators and offers a smooth transition from Reactive to Predictive to Pro-active maintenance.

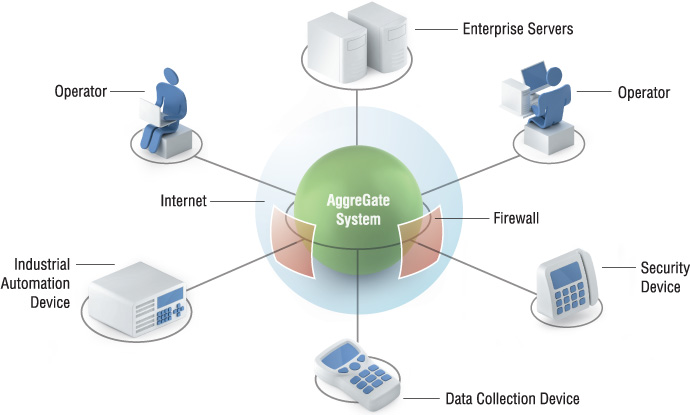

The general architecture of remote condition monitoring includes sensors for data collection, which are placed on an asset to collect raw data, which is transferred over a wired or wireless network to the data collection center or central control room or to the cloud. This raw data can be further analyzed to identify the trends and patterns, which results in the understanding the health status of an asset. Before implementing remote condition monitoring technology, it is always crucial to plan various factors such as sensor technologies, placement of sensor, collecting and handling of statistical data, information distribution, and data formatting, alarm monitoring, device supervision and maintenance among other things additionally to the volumes of the data generated by a real-time sensor network.

As infrastructure owners experience multiple challenges, efficient and timely maintenance interventions are essential to ensure trains operate to the published timetable without delays or interruptions to service. Therefore, it is critical to monitor key assets with real-time information that will support: right time interventions, changes in the existing maintenance regimes, and re-designing of an asset.

As infrastructure owners experience multiple challenges, efficient and timely maintenance interventions are essential to ensure trains operate to the published timetable without delays or interruptions to service. Therefore, it is critical to monitor key assets with real-time information that will support: right time interventions, changes in the existing maintenance regimes, and re-designing of an asset.

The remote condition monitoring system measures important parameters on the asset and concludes if the measurements are suggesting a healthy or a defective asset. If a defect is suspected to be found, a message is sent to maintenance personnel who inspect the asset and fixes it. This method is useful in detecting faulty behavior in an asset before any failure occurs which gives the possibility of correcting it at maintainer convenience avoiding disturbance to traffic.

Remote condition monitoring helps to increase the performance and availability of assets. Thus, it can prove a good solution for an improved and successful rail operation. The industry needs to diverge from traditional fix on fail to more preventive and practical approaches using RCM and it’s time for them to explore in the direction of intelligent and effective infrastructure.